Perfect Quote-to-Cash with Acumatica – Phase 2

Phase 2 – Produce and Fulfil

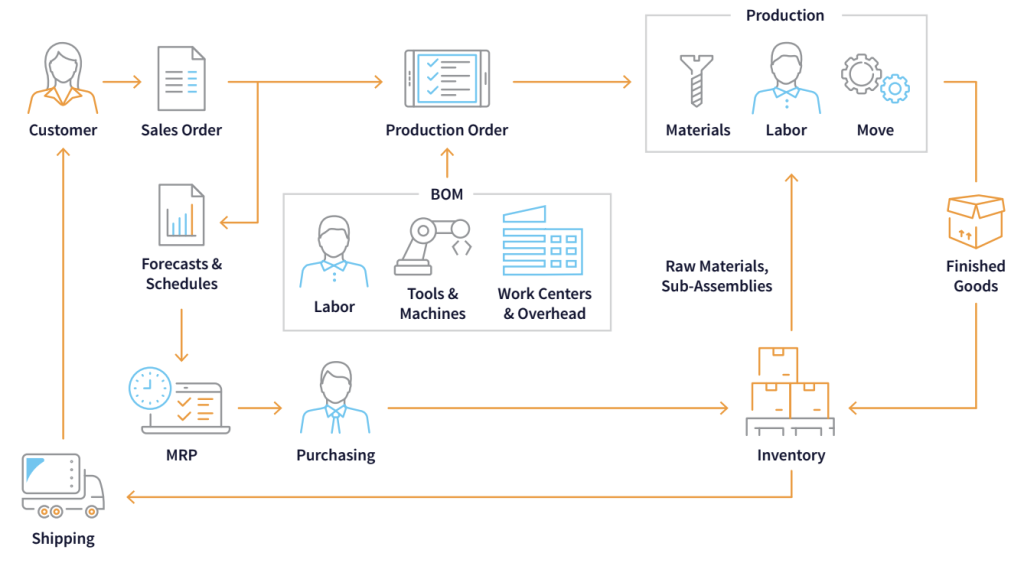

Step 1: Production Order Creation

In make-to-stock manufacturing, production orders are created based on demand forecasts. Sales orders consume this forecasted demand, while MRP provides planners with production order quantities, dates, and other recommendations to maintain inventory levels. Planners consolidate production orders to address multiple demand sources.

Job shops, configure-to-order, and engineer-to-order manufacturers create production orders directly from sales orders, which are then scheduled for manufacturing. Make-to-order manufacturers also create production orders from sales orders but use MRP for managing dependent demand on subassemblies and raw materials. Customer service representatives utilise Capable to Promise (CTP) to check product availability for sale or shipment.

Project-centric manufacturers generate production orders from project tasks, linking them for costing and billing. MRP helps with downstream planning for subassembly production and raw material purchases.

Step 2: Scheduling

Production orders are scheduled either manually or automatically, forward from the current date or backward from the requirement date. Managing shop calendars, shifts, and crew labour maximises throughput. Schedules handle finite and infinite capacity constraints, and prioritise critical orders first. Dispatch reports show which production order operations are scheduled by resource.

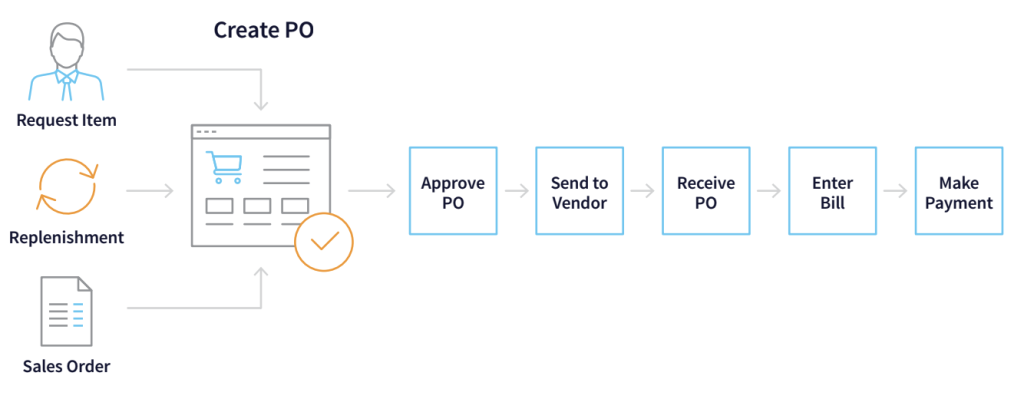

Step 3: Material Planning

Purchase required raw materials via the Purchase Order Entry screen. Matrix grids streamline purchases, while the Purchase Order Requisition app enables vendor bids on new items. MRP uses inventory settings (safety stock, min/max levels) to recommend purchase orders when inventory is low. Warehouse relationships allow transfers, and Acumatica supports drop-shipments and blanket orders with release dates. Quality control on receipts is supported, and backorder items trigger notifications.

Step 4: Production

Employees issue materials to production or use backflushing for WIP cost allocation. Barcode scanners improve data accuracy for lot and serialised items, ensuring correct materials are issued. Labour transactions are recorded on mobile devices via the Manufacturing Data Collection app, syncing time with Acumatica Payroll. Managers monitor production through dashboards for real-time shop floor insights.

Step 5: Fulfilment

Completed production orders reduce WIP costs and update finished goods inventory, readying items for fulfilment. Smaller manufacturers may pick, pack, and ship in one step; larger manufacturers split these tasks.

Picking: Items are picked manually or through advanced wave/batch methods, validated with barcoding.

Packing: Barcoding captures each packed item. Acumatica supports custom packaging and unit conversions.

Shipping: Shipments are prepared with carrier integration for shipping options, documentation, and cost calculations. Acumatica supports small parcel, LTL, and truckload shipments.

Related Articles

-

- Maximise Your Tech Investment With Acumatica

- Revolutionise Your Distribution Business With Acumatica

- Acumatica Distribution Edition Overview

- Improve Inventory Management With Acumatica

- Unlock Valuable Business Insights With Acumatica

- Introducing Acumatica CRM

- Boost Growth Through Enhanced Manufacturing Efficiency

- Your Free Guide to Choosing a New ERP System

- What Is Cloud ERP?

- 5 Benefits of Cloud ERP

- How Acumatica Improves Lead Generation For Manufacturers

- 5 reasons to upgrade from Quickbooks to Acumatica.

Need more information? Get in touch with us now.