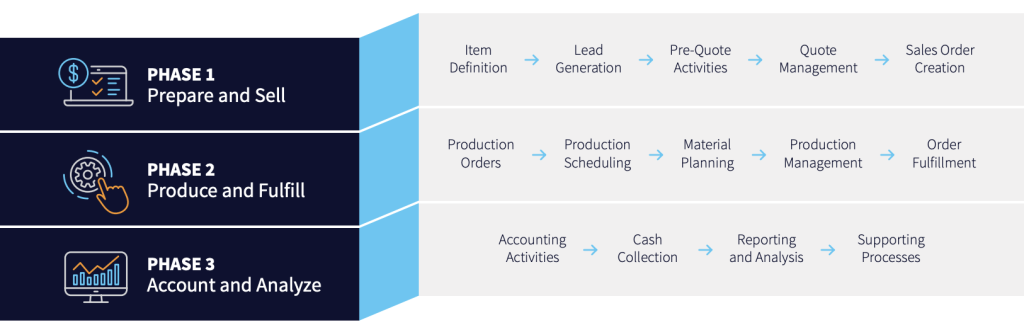

Perfect Quote-to-Cash with Acumatica – Phase 1

Get Paid Faster with Configurable Quote-to-Cash Workflows

Each manufacturer has unique quote-to-cash requirements. Some manufacturers predict demand, produce stock, and fulfill orders from inventory. Engineer-to-order manufacturers rely on CAD tools to design custom products, following customer specifications or internal designs. Configure-to-order manufacturers allow customers to choose features and options, creating tailored items. Job shops, which typically do not stock products, depend on accurate estimating to deliver quoted products to customers.

Acumatica Manufacturing Edition offers a versatile solution to support various quote-to-cash workflows. With robust tools for managing leads, sales, inventory, purchasing, production, shipments, and accounting, the platform adapts to different manufacturing needs. Additional modules extend quote-to-cash capabilities to support retail and e-commerce sales, field service appointments for installations and repairs, and project accounting for jobs involving manufactured goods.

Step 1: Item Definition

Manufacturers maintain stock and non-inventoried items used in sales, production, projects, and services. Deferral codes ensure accurate revenue recognition for sales of service, support, and other non-inventoried items. Generate unique items with Matrix Items using attributes such as length, width, style, colour, and more. Contract items are also configured as non-inventoried to define services with specific pricing and provision policies for the initial item sold, with different non-stock items available for renewals.

Stock ItemsAcumatica offers nine methods for creating raw material and finished goods stock items: • Import items from vendor files • Manual item creation • Copy items from similar items • Create items from templates • Convert items from requisitions • Generate finished goods from estimates • Create items from the product configurator • Import items from CAD or PLM applications • Create items using attributes with matrix items |

Non-Inventoried ItemsNon-inventoried items can be included in bills of material BOM) and quotes for added flexibility: • Professional and field services • Product documentation • Digital downloads • Manufacturing and office supplies • Billable expenses • Maintenance and repair supplies • Consumable tooling • Support contracts • Other non-inventoried items |

Step 2: Lead Generation

The marketing department then creates targeted lists and launches campaigns to generate leads. Opportunities are assigned to sales representatives according to product line, sales territory, or other customised criteria. For each opportunity, activities can be scheduled, and completed tasks are logged with notes. Leads that are disqualified can be sent back to marketing for further activities.

Marketing activities generate business leads through events, email, inbound website traffic, trade shows, telemarketing, cold calls, referrals, and more. Import and manage marketing lists to support email, direct mail, telemarketing, and various campaign types. Plan and execute marketing tasks and events to build qualified business opportunities for sales, projects, and services, helping your organisation grow.

Opportunity Management

The sales team converts qualified leads into new business opportunities. Configure sales processes, schedule tasks, add notes, and attach documents to streamline the management of each opportunity. Opportunities allow sales professionals to create and manage quotes and sales orders, generate and schedule service orders, and configure manufactured finished goods for each line item in the opportunity.

Step 3: Pre-Quote Activities

The quote-to-cash process varies across make-to-stock, make-to-order, configure-to-order, engineer-to-order, and project-centric types. The next step defines the finished goods and services for the sales quote.

Make-to-Order (MTO): Manufacturing Estimates

Job shops and MTO manufacturers create manufacturing estimates for new finished goods from scratch or by referencing previous estimates, bills of material, or production orders. Estimates can be initiated directly from CRM or manufacturing applications. Estimators set product quantities, component operations, and tooling costs and adjust labour, machine time, materials, and other costs, applying markups as needed.

Customer prices are based on cost elements, markups, and quantity, with tooling costs spread across estimated quantities. Quotes can be sent to customers for approval, and approved estimates are quickly converted into stock items.

Project-Centric Manufacturing: Project Accounting Integration

Project accounting creates estimates for multi-task customer quotes, linking finished goods to project tasks. Projects consolidate production costs, purchases, and expenses for complete project budgets, timelines, and billing.

Make-to-Stock (MTS): BOM and Routing

Make-to-stock manufacturers use bills of material (BOM) and routing to define finished goods and subcomponents. BOMs, imported or created from scratch, link to labor operations, supporting tooling needs, overhead costs, and outside processing. Demand forecasts guide material planning for finished goods and raw materials.

Configure-to-Order (CTO): Product Configurator

Sales or customer service reps use a product configurator to create customised items based on attributes and options. Configurations can be created from scratch or past definitions. Configurator entries generate BOMs, routings, and inventory records for pricing and cost roll-ups.

Engineer-to-Order (ETO): CAD/PLM BOM

ETO manufacturers convert CAD engineering designs into inventory and manufacturing BOMs. The Acumatica for Arena PLM Native Connector integrates these into the ERP system. Use Engineering Change Control for engineering change requests (ECR) and orders (ECO) with approval workflows and audit trails.

Purchase Order Requisitions

For new inventory items, Purchase Order Requisitions are sent to vendors to solicit bids, with workflows for internal approval. Once a requisition and sales quote are approved, the winning bid is converted into inventory items.

Step 4: Quote Creation

Acumatica provides workflows for standard manufacturing processes that can be customised to specific business needs. Manufacturers can create quotes for product sales, larger projects, field services, or support contracts. Sales quotes convert to sales orders, service quotes to service appointments, and approved project quotes to defined projects and tasks. Contract quotes are easily converted to new or renewal contracts.

Sales Quotes

Create quotes directly from sales order entry or CRM opportunities, copying from prior quotes or sales orders as needed. Quotes for manufactured items can reference estimates, and customer service can use the product configurator to create tailored finished goods. Acumatica offers flexible pricing, including quantity and volume discounts. Set up discount rules or allow the system to automatically apply the best discounts. Approvals for discounts can be managed through workflows, and supervisors can approve requests via mobile.

Project Quotes

Service organisations can generate project quotes, using templates to streamline the process. Quotes include estimates, tasks, billing details, and tax information, allowing calculation of costs, expected revenue, and profit margin. Quotes convert easily to projects, including labor rates, tasks, notes, and files.

Service and Support Quotes

One-time and long-term service or support quotes can be created in Acumatica and converted to sales orders, service appointments, or support contracts.

Electronic Signatures with DocuSign

Seamlessly integrated with DocuSign, Acumatica automates approvals for quotes and sales orders. Approved quotes sync into Acumatica with signatures, and workflows convert quotes to sales orders, notifying the sales manager.

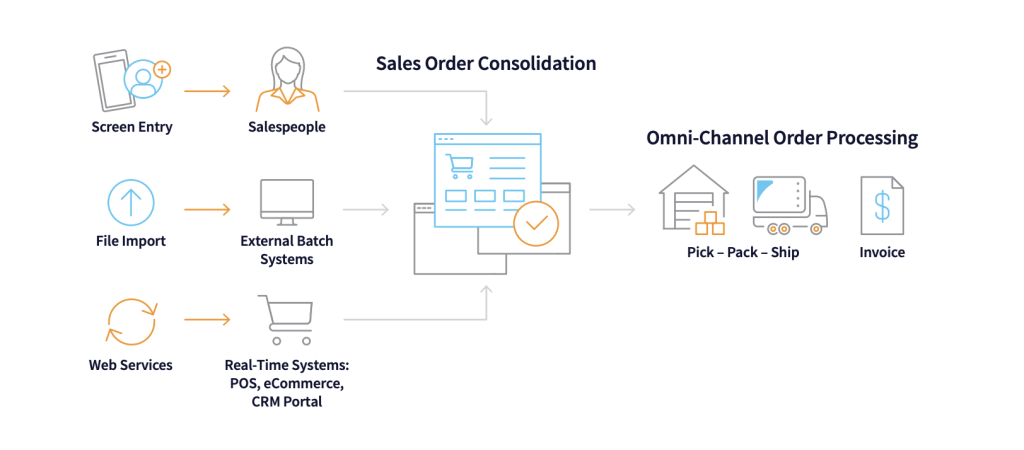

Step 5: Sales Order Creation

When opportunities convert to sales orders, prospects become customer accounts. Workflow notifies accounting to finalise setup, including credit checks, terms, limits, shipping locations, and contacts. Reserve stock to ensure fulfilment, or for smaller operations, skip pick and pack to generate shipments directly if stock is available. Project quotes can be converted to projects, and service quotes to service orders. Sales orders can also be generated from POS transactions, online storefronts, file imports, or EDI transactions via connected applications.

Related Articles

-

- Maximise Your Tech Investment With Acumatica

- Revolutionise Your Distribution Business With Acumatica

- Acumatica Distribution Edition Overview

- Improve Inventory Management With Acumatica

- Unlock Valuable Business Insights With Acumatica

- Introducing Acumatica CRM

- Boost Growth Through Enhanced Manufacturing Efficiency

- Your Free Guide to Choosing a New ERP System

- What Is Cloud ERP?

- 5 Benefits of Cloud ERP

- How Acumatica Improves Lead Generation For Manufacturers

- 5 reasons to upgrade from Quickbooks to Acumatica.

Need more information? Get in touch with us now.